Meet Our Award Winning ICF Blocks

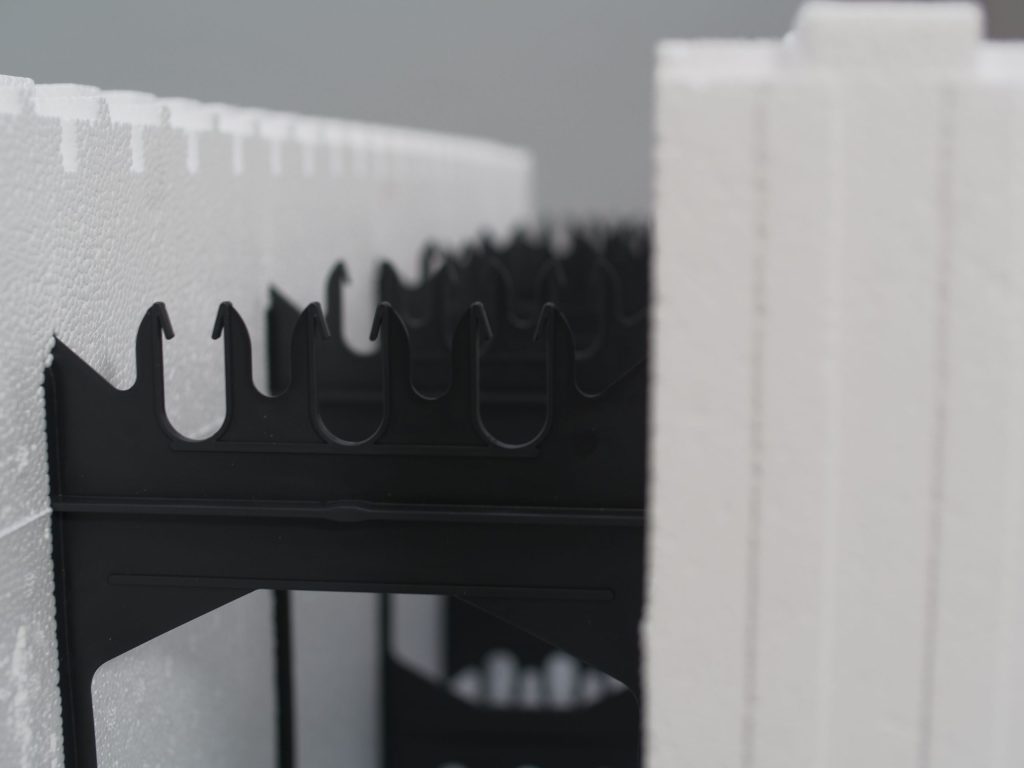

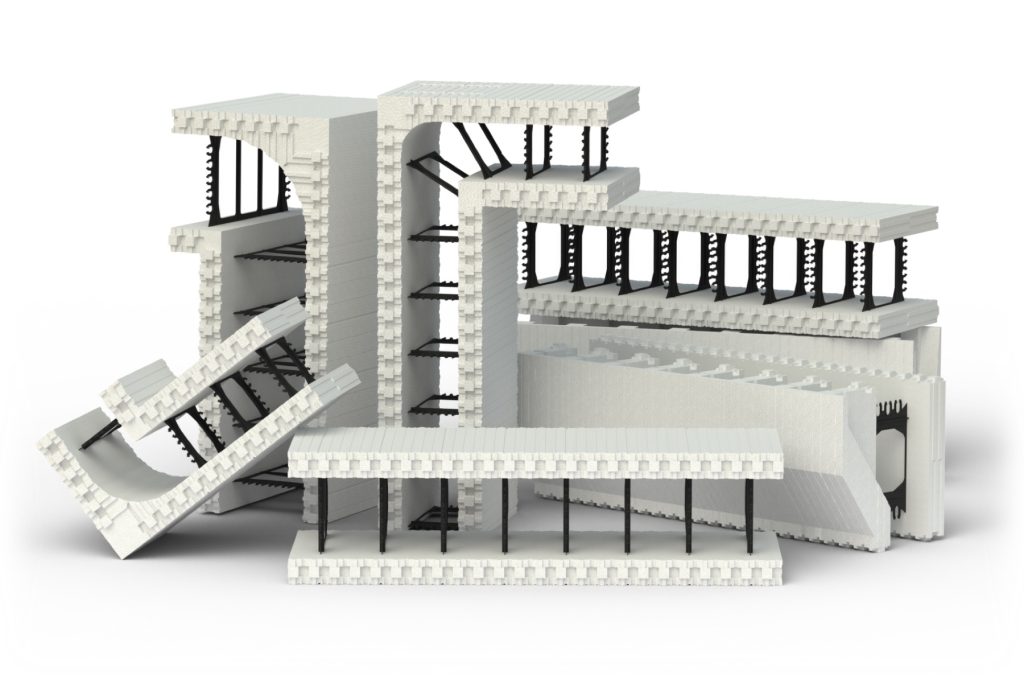

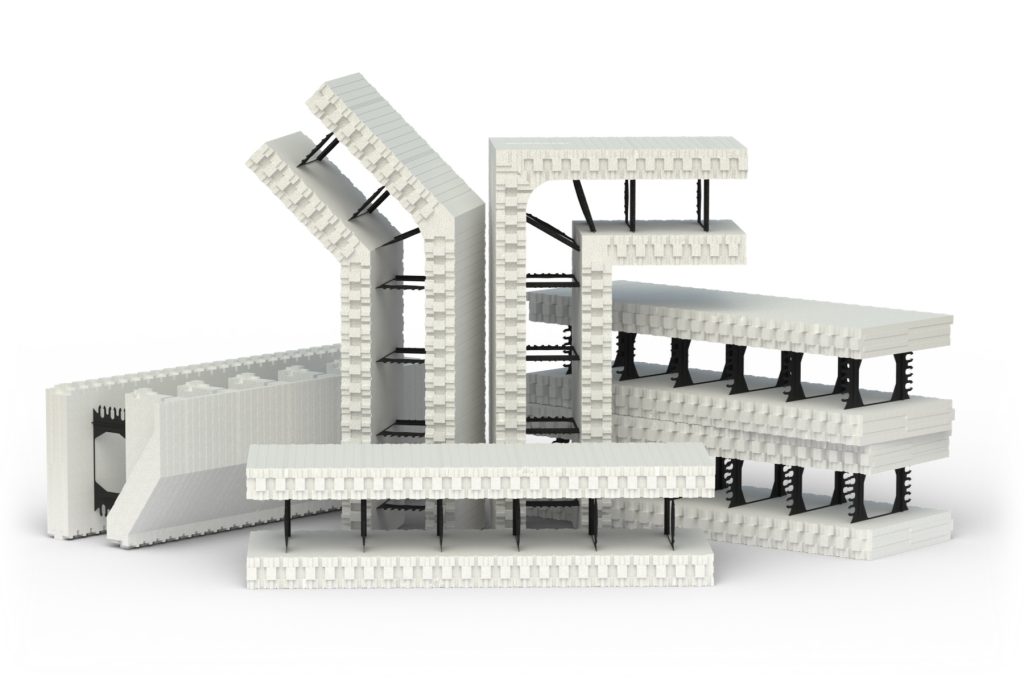

Amvic™ Insulated Concrete Forms (ICF) are a stay-in-place, 5-in-1 concrete forming system incorporating structure, insulation, an air/vapor barrier and a finish attachment to create a cost-effective, resilient and environmentally friendly construction system. Amvic™ ICF is revolutionizing modern construction and changing the way we build for a greener tomorrow.

Amvic™ ICF R22

Amvic™ ICF R22 is a cost-effective ICF block providing excellent performance and value to any construction project. The combination of patented FormLock™ interlock and reversible block makes for a fast and easy installation, while considerably reducing job site waste. A wide range of available forms and core sizes allows for limitless design possibilities.

Product Features

- Thermal Resistance

- R22 hr.ft2.F/Btu (3.87 m2K/W)

- EPS Panel Thickness

- 2.5” (63.5mm)

- Web Spacing

- 6” (152mm) on center

- Available Core Sizes

- 4” (102mm), 6” (152mm), 8” (203mm) at 16” (406mm) high & 10” (254mm), 12” (305mm) at 24” (610mm) high

- Block Types

- Straights, 90° corner, 45° corner, Taper top, Brickledge, T-block, Radius

Applications

Below-grade foundation walls

Frost walls

Additions to existing buildings

Multi-story residential and commercial construction

Demising walls in high-rise construction

Amvic™ ICF R30

Designed to meet ever-increasing energy efficiency requirements, Amvic™ ICF R30 is a higher performance ICF block where EPS panel thickness has been increased by 30% making it the highest R-value of any factory assembled block in the industry. The patented FormLock™ interlock has also been improved with the addition of integrated drainage channels.

Product Features

- Thermal Resistance

- R30 hr.ft2.F/Btu (5.28 m2K/W)

- EPS Panel Thickness

- 3.25” (82.5mm)

- Web Spacing

- 8” (203mm) on center

- Available Core Sizes

- 6” (152mm), 8” (203mm) at 16” (406mm) high

- Available Blocks

- Straights, 90° corner, 45° corner, Taper top, Brickledge

Applications

Below-grade foundation walls

Above-grade walls

Frost walls

Additions to existing buildings

Multi-story residential and commercial construction

Institutional buildings

Amdeck Insulated Concrete Floor & Roofing System

Designed for both commercial and residential insulation projects, Amvic™ Insulated Concrete Floor & Roofing System is an insulated, stay-in-place concrete form that can be used for virtually any floor or roof construction. It is a 4-in-1 system offering structure, insulation, sound attenuation and finished attachment. Amdeck Pro is designed for commercial applications with compact modular design allowing the forms to be easily transported and installed even in smaller spaces while the Amdeck Eco is designed for low-rise residential applications with longer sections increasing construction speed.

Amdeck Pro Product Features

- Thermal Resistance

- R19 hr.ft2.F/Btu (3.34 m2K/W)

- Steel Joists Thickness

- 16ga, 14ga or 12ga

- Size of Form

- (h) 12” x (w) 32” x (l) 24” / (h) 305mm x (w) 813mm x (l) 610mm

AmBuck™ Insulated Block-Out System

AmBuck™ Insulated Block-Out System is a stay in place buck formwork manufactured using Type II/ Type 2 closed cell, Expanded Polystyrene (EPS) panels for ICF construction walls. AmBuck™ eliminates the need for wood and vinyl block-outs, while being a cost effective and energy efficient solution. It is an effective approach to creating block-outs in ICF walls and can enhance any ICF project. AmBuck™ allows for easy assembly and can accommodate any 6” and 8” R22/R30 ICF system.

AmBuck™ Product Features

- Material Specification

- Type II (ASTM C578) / Type 2 (CAN/ULC-S701.1) Expanded Polystyrene (EPS)

- Thermal Resistance

- 4.2 F.ft2.hr/Btu per inch (0.74m2K/W per inch) (ASTM C518)

- Compressive Strength

- 20 psi (138 kPA) (ASTM D1621)

- Compatibility

- Compatible with 6” (152mm) and 8” (203mm) core Amvic™ R22 and R30 ICF systems.

Technical Resources

- Alleguard QAI Product Listing (Link)

- Alleguard Specifications – 031119 (PDF)

- Amvic™ ICF – 10 Step Swimming Pool Construction Guide (PDF)

- Amvic™ ICF – CA Design Guide (PDF)

- Amvic™ ICF – CCMC Report (Link)

- Amvic™ ICF – ICC-ES- ESR 1269 Report (PDF)

- Amvic™ ICF – US Design Guide (PDF)

- Amvic™ ICF – Cold Weather Concrete Placement (PDF)

- Amvic™ ICF – Curb Detail (PDF)

- Amvic™ ICF – Fastener Load Testing (PDF)

- Amvic™ ICF – Fire Resistance Rating (PDF)

- Amvic™ ICF – Moisture Protection for Frost Walls (CA) (PDF)

- Amvic™ ICF – Rebar Sizes (PDF)

- Amvic™ ICF – STC Rating (PDF)

- Amvic™ ICF Installation Manual (PDF)

- ICFMA CAN Type 9 Building Engineering Manual (PDF)

- QAI Listing (Link)

- Amvic™ ICF – R22 Product Data Sheet (PDF)

- Amvic™ ICF – R30 Product Data Sheet (PDF)

- Amvic™ ICF Accessories – Product Data Sheet (PDF)

- Amvic™ ICF – 10 Step Construction Guide (PDF)

Download Brochure & Specs

Our innovative, sustainable, and resilient ICF blocks are the ideal solution for long-lasting buildings and sustainable construction.

ICF Construction Accessories

Brick Ledge Reinforcer

The Amvic™ ICF Brick Ledge Reinforcer is an engineered ICF brick ledge reinforcement system that is designed to replace conventional rebar in the Amvic™ ICF brick ledge forms. It is a single pre-assembled, 4ft (1.2m) long deformed welded wire reinforcement piece that is placed directly into Amvic™ ICF’s brick ledge. Conventional brick ledge forms must be reinforced with a line of horizontal rebar and stirrups between the horizontal bars in both the ledge and the wall area of the brick ledge form.

Benefits

The Amvic™ ICF Brick Ledge Reinforcer eliminates the horizontal rebar and stirrups in the ledge area allowing the Reinforcer to be easily placed into the form in one step; providing cost savings of up to 30% when factoring in materials and labor with pre-bent or field fabricated rebar reinforcement.

The Reinforcer is compatible with Amvic™ ICF’s Standard R22 brick ledge forms in both 6” and 8”, the Amvic™ ICF R30 Plus 6” and the fabricated brick ledge extension. Once placed in the ICF form, the Amvic™ ICF Reinforcer does not need to be butted, lapped or tied to each other.

Brick Ledge Extension

The Amvic™ ICF Brick Ledge Extension is designed to support masonry veneer exterior finishes where using a speciality brick ledge ICF block is not available. It is compatible with Amvic™ ICF R22 and R30 blocks in all core sizes and can be installed at any height, angle and side of an ICF wall. The Brick Ledge Extension comes fully dismantled from the factory in compact packaging to save space and cost during shipping. Each kit is composed from two parts, one ledge and either 12 (for R30 ICF) or 16 (for R22 ICF) inserts.

Part 1 (ledge) – Length 8’ (2438mm) x Width 5” (127mm) x Height 13.5” (343mm)

Part 2 (insert) – 9.5” (241mm) x 4.5” (114mm) and 1.5” (38mm) thick

Buck Brace

There is a need in the ICF industry for a better way to brace ICF openings. The patent-pending Burmon Buck Brace is engineered to brace the horizontal pressures of the concrete during the pour in the ICF Bucks. The Burmon Buck Brace eliminates all horizontal wood bracing, saving on lumber and labor costs.

Features

- Faster and more convenient than cutting lumber on the job

- Adjustable to suit most widths of 6- and 8-inch core icf blocks

- Engineered and designed for horizontal bracing

- Cost effective, long lasting

- Less waste, more efficient

- Made from 18 gauge galvanised steel

- Works with wood, steel and polystyrene bucks

- Reduced blocked openings making passage through openings easier

Plumwall ICF Bracing System

Plumwall provides a complete bracing system for ICF construction for quick, accurate and professional installations. The unique one-man alignment control is located at the platform level making it ideal for adjustments of freshly poured concrete. This highly durable and flexible system can be configured for tall wall applications and is available in either All-In-One or 3-Piece configuration.

Available configurations

All-In-One system has a unique fold-up design ensuring that all parts make it to the construction site and back to storage after each project. The light weight brace (54lb/24.5kg) can be easily carried by a single person, unfolded, anchored and be ready to use in a short span of time.

The 3-Piece system is composed from an outrigger and a 14 gauge galvanized steel strongback, both of which connect to the pin-on platform bracket thus allowing for a quick and easy assembly on site while maintaining flexibility of the platform height and ease of storage.

Tall Wall system and accessories are available on special order which allows for a maximum wall bracing height of 24ft (7.3m)

Platon Foundation Wrap

Drainage membrane for below grade ICF foundations

Platon is a rugged, dimpled high-density polyethylene (HDPE) membrane for below grade foundation walls. It creates a vapor impermeable barrier and an air gap, allowing for moisture control. The wet soil is kept away from the foundation walls and if any moisture does find its way past the membrane, it is carried to the foundation drain by the air gap drainage path. It is economical and easy to install in any weather condition with the ability to easily bridge cracks of up to ¼” (6mm) in width. An ideal solution to be used with a peel-and-stick membrane.

Soprema Colphene ICF

Self-adhering membrane for below grade ICF foundations

Colphene ICF is high quality peel-and-stick membrane composed of SBS modified bitumen with tri-laminate woven polyethylene facer and silicone release film. The membrane is designed to be used for either waterproofing or damproofing for below grade ICF foundation walls. It has high tensile strength and puncture resistance while maintaining great flexibility.

It can be installed with or without primer over clean and dry ICF walls depending on the exterior temperature and application. It has a very consistent thickness (40mil / 1mm) and comes in rolls of 36in x 75ft (0.9m x 22.9m). Colphene ICF is available in two grades, summer and winter, with application temperatures of 50-122°F (10-50°C) and 14-50°F (-10-10°C) respectively.

Soprema Elastocol Stick H2O

Primer designed to improve adhesion for waterproofing membranes

Elastocol Stick H2O is a single component water based primer designed to be used in conjunction with self-adhering waterproofing membranes on most substrates. It is an excellent choice when the use of solvent based primer is not recommended. Can be applied with either a brush, spray gun or a roller.

DuRock Fiberglass Mesh

High impact reinforcing fiberglass mesh for parging

DuRock’s Fiberglass Mesh is a 5oz (142g) high impact alkali-resistant fiberglass mesh designed to be used with B2000 parging base coat. Provides increased flexural strength to the base coat while improving the bond to the substrate. It comes in rolls of 39”x144’ (1m x 44m).

DuRock B2000

Cementitious parging coat for use on above grade ICF walls

B2000 is an acrylic-modified cementitious dry mix base coat designed for use over Expanded Polystyrene (EPS) Insulated Concrete Forms (ICF). It forms a strong but flexible crack resistant base coat that is intended for use on the exterior, above grade portion of ICF foundation walls. It has high flexural and bond strength, is vapor permeable, with low water absorption and excellent freeze-thaw resistance.

ICF HV Hooks

ICF HV Hooks for simultaneous horizontal and vertical locking

The Amvic™ ICF Hook is an all-in-one metal wire clip designed to replace conventional nylon cable ties in ICF construction. The hook is engineered with seven bends to provide it with simultaneous horizontal and vertical locking capacity. It is available in two sizes; HV22 for Amvic™ ICF Standard (6” web spacing) and HV30 for Plus ICF forms (8” web spacing).

Benefits

- Vertical and horizontal tying in a single step

- All weather installation, does not break in low temperatures

- Easy to install with snap in place installation

- Can be removed if repositioning is needed

- One hook every 4’ (1.2m) or every two courses

Installation

Step 1: Place the bottom of the hook under the top portion of the lower block’s web.

Step 2: Bring the top portion of the hook up and over the top of the two webs and snap it in place. Pull the lip up to unhook it.

ICF Screws

Multi-use ICF Screws for ICF bracing, bucking and cleats

The Amvic™ ICF screw is designed to help increase efficiency and reduce cost during the construction process. Its hardened and galvanized construction offers superior all-weather performance and durability. The coarse thread works well with the plastic ICF webs with increased holding capacity and pullout strength. The combination of the hex head and the loose washer makes for a quick and easy screw removal. In addition, the loose washer prevents screws from being recessed into lumber when fastening to the web of an ICF form. Available in 2” (51mm) or 3” (76mm) lengths.

Zip Ties

Zip ties to secure ICF blocks during installation

Amvic™ ICF’s heavy duty zip ties have a tensile rating of 175lbf (79.38kgf) and offer a cost-effective method for quick and easy securement of ICF blocks together, either in a vertical or horizontal configuration.

Each bag contains 50 black nylon ties that are UV stable and can be used for interior and exterior applications. The ties come in two lengths, 36” (0.9m) for R22 ICF and 48” (1.2m) lengths for R30 ICF. The cables ties should not be installed in temperatures below -4°F (-20°C).

Simpson Strong-Tie

ICFVL Ledger Connector System

The ICFVL connector system by Simpson Strong-Tie is an engineered floor mounting system for ICF construction. It is designed to provide both vertical and lateral in-plane performance. The system replaces the need for traditional anchor bolts with better on-center spacing, faster and easier installation and no protrusions. The system is composed of two primary components, ICFVL and ICFVL-W/CW.

Components

- ICFVL is installed prior to concrete placement and acts as an exposed flange. The legs of the flange are embossed for additional stiffness while the holes enable concrete to flow through and around the connector.

- ICFVL-W is a ledger connector used for two-bys ledger board installation.

- ICFVL-CW is a ledger connector used for LVL ledger board installation.

Installation

For installation, use chalk or a laser level to mark the bottom of the flange at the required on-center spacing. Use the flange legs to mark kerfs locations. Cut kerfs as marked and insert the ICFVL flange flush to the face of the ICF. After the concrete has cured, slip the appropriate ledger connector underneath the ledger and install eight screws partially into the ledger. Position the bottom of the ledger level to the chalk line or the laser and drive the screws through the wood and into the flange.

For steel ledger installation a ledger connector is not required. Position the bottom of the ledger to the chalk or laser line against the flange. Use four appropriate drill point screws through the ledger and into the flange. The screws should be evenly spaced and at least ½” (13mm) away from the edge of the flange.

Building With ICF

Cost-efficient, energy-efficient and high-performing, insulated concrete forms are the perfect choice for insulation applications in walls, foundations, and roofing.

Energy Efficiency

ICF wall has minimal thermal bridging due to the dual layers of continuous insulation. The sandwich wall assembly creates a very airtight envelope reducing undesired air leakage. The combination of the high thermal resistance, air tightness and thermal mass makes for a very energy efficient building.

Indoor Comfort

The combination of increased air tightness and continuous insulation creates a superior building envelope which has no drafts and maintains the conditioned space within the optimal thermal comfort range. The addition of the concrete mass contributes to the highly sound absorbent walls (high STC rating) giving the occupants a quiet comfortable interior.

Sustainability

The highly energy efficient envelope can reduce the building’s carbon footprint while the durable and robust structure fortifies it against nature’s unavoidable hazards giving ICF buildings long service life. Additionally, wall components can be made from recycled materials minimizing the impact on the environment through reduced raw material demand.

Strength and Resilience

The monolithic reinforced concrete core makes for a much stronger structure when compared to framed construction. The combination of high strength and fire resistance rating (FRR) creates superior resistance to both natural and man-made disasters. The wall components do not lose their structural integrity when exposed to high moisture environments.

Why Amvic™ ICF is the Right Choice

Developers

Ensure a sustainable, energy efficient building envelope with significantly lower long-term maintenance requirements.

Contractors & Installers

Quick and easy installation that reduces waste and increases job site efficiency.

Architects & Engineers

Sustainable, disaster resilient construction which allows for a high flexibility in design.

Homeowners

Energy efficient homes that reduce utility costs and create a comfortable and healthy environment.

ICF Certification & Architect Training

Alleguard offers ICF training for contractors & continuing training credits for architects. Register for one of our on-demand ICF installation training webinars today.

ICF Project & Applications

Green Building with Amvic™ ICF

Amvic™ ICF blocks are an excellent alternative for environmentally friendly and long-lasting buildings. There are several elements that make Amvic™ ICF a preferred choice for sustainable construction.

Reduces harmful emissions

Alleguard manufacturing facilities use steam and cold water to produce ICF. No harmful chemicals like CFC’s, HCFC’s, formaldehyde are used in Alleguard’s manufacturing process eliminating off-gassing and greatly reducing harmful emissions.

Minimizes waste

Amvic™ ICF can generate as little as 1% construction waste, greatly reducing landfill bound waste.

Uses recycled materials

Amvic™ ICF webs are manufactured using 100% post-industrial recycled polypropylene which effectively means that over 60% of the weight of an Amvic™ ICF block is comprised of recycled materials.

Contributes to LEED® certification

The USGBC’s LEED® Certification program provides a framework for assessing building performance and sustainability based on water savings, energy efficiency, materials selection and indoor environmental quality. Amvic™ ICF may contribute to 32-35 points towards LEED® certification.

SUBSCRIBE

Get Our Latest Insights

Contact Us

Interested in Learning More?

Whether you need a custom solution for a unique project or have a question, we’re here to help.