Amrad: Insulated Radon Gas Mitigation Panel

Innovative rigid insulation panel for under slab depressurization systems

About Amrad: Insulated Radon Gas Mitigation Panel

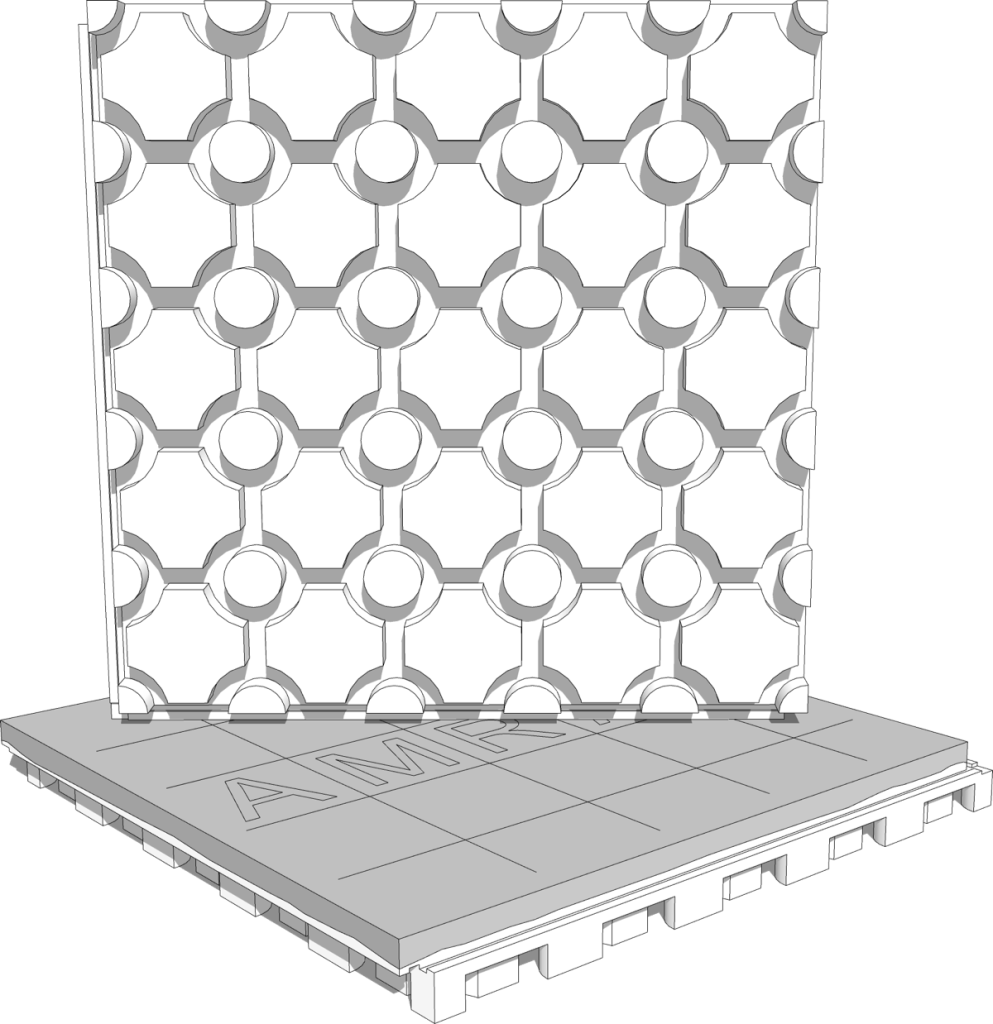

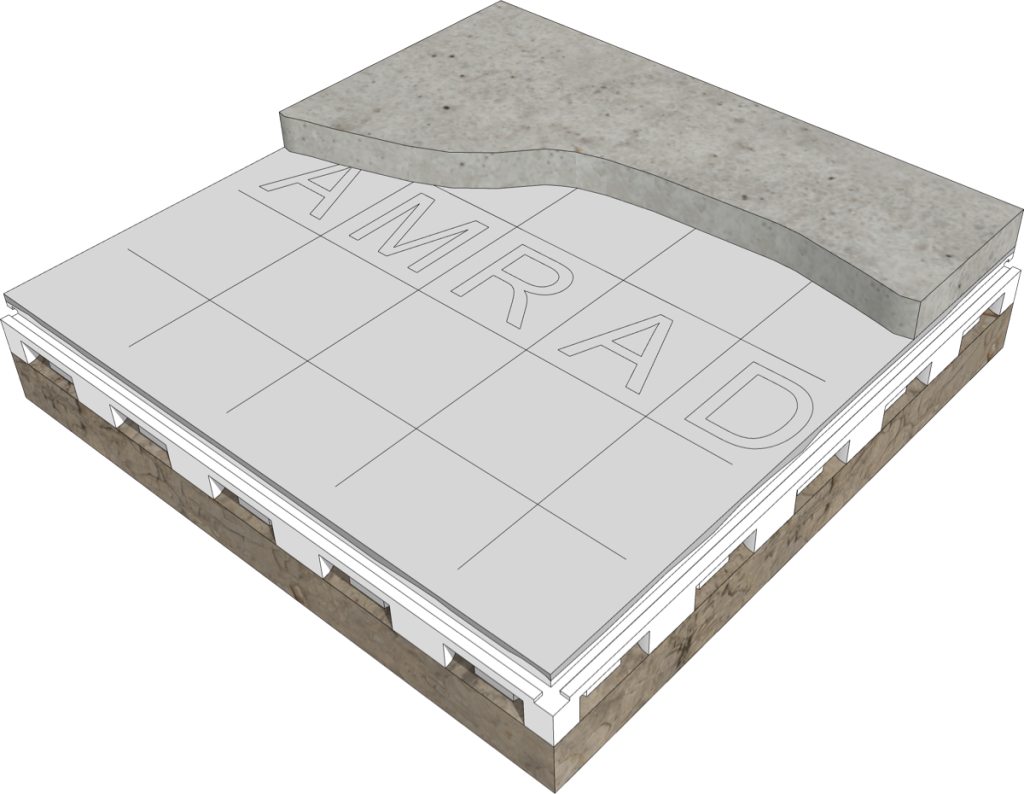

Amrad is an insulated under slab depressurization panel and a key component in a radon gas mitigation system. The void created by the integrated channels serve as an air gap for soil gas collection. Radon gas is able to vent out to the exterior through the use of a connected PVC piping with a continuously running exhaust fan. This panelized solution with its unique channel design, void percentage, film and foam density creates a strong and durable panel, giving builders the ability to build an insulated concrete slab while meeting radon building code requirements and improving the indoor air quality for the occupants.

The channel pattern and ratio of solid to empty allows Amrad to replace 4” (102mm) of clean granular fill as normally required by the building code. In addition, the air gap created by the channels serves as a capillary break between the soil and slab, greatly reducing moisture related issues. Amrad’s High Impact Polystyrene (HIPS) film serves a dual function by providing the required vapor barrier under the concrete slab while acting as an air barrier to prevent any radon gas from infiltrating into the interior space. The Amrad film replaces the need for a dedicated soil gas retarding membrane as required by the building code.

Product Features

- Compressive Strength

- 20 psi (152 kPa)

- Thermal Resistance

- R12 (RSI 2.11) R16 (RSI 2.82)

- Vapor Permeance

- <0.1 US perms (5.4 ng/Pa.s.m2)

Technical Resources

Download Brochure & Specs

Why Use Amrad?

Contractor & Installer

Smaller panels and film lamination decrease damage and installation time.

Architect & Engineer

Innovative and certified panel design for radon gas mitigation systems.

Developers

Streamlined installation process while offering superior energy efficiency and durability.

Homeowners

Consistent and durable high-performance system offering comfort and peace of mind.

The Alleguard Advantage

With a combined 60-year history and proven track record of supporting our customers’ visions, Alleguard is strategically built from the ground up to expand and shape your business. Whether you’re in construction, protective packaging, cold-chain or other industries, we are relentless in going the extra mile to help your business succeed.

About EPS

EPS has high R-value retention, is fully recyclable, and is easily customizable. EPS is made without ozone-harming compounds or any kind of dye. It is available in a variety of compressive strengths and has superior bonding capabilities. Best of all, EPS will save you time and money. So the real question is: Why not EPS?

Amrad Panel Benefits

Superior Thermal Insulator

Amrad has exceptional Long-Term R-Value Retention (LTTR) as well as increased thermal resistance in lower temperatures.

Durable, Lightweight, Flexible

Each panel is easy to handle due to the low weight and can be easily cut.

Improved Indoor Air Quality

Amrad does not contain CFCs or HCFCs, no off-gassing and does not promote growth of mold and mildew.

Increases Comfort & Energy Savings

Acts as continuous insulation in the building envelope, reducing thermal bridging and energy consumption while improving comfort.

Built-in Air & Vapor Barriers

When the joints are taped and sealed functions as both an air and vapor barrier.

Environmentally Friendly

EPS foam can be recycled and uses only steam and water during manufacturing.

Shaping A More Sustainable World

Sustainability is one of our top priorities, both for our products themselves and for what our products make possible. Manufactured without ozone-damaging compounds, recyclable and endlessly reusable, EPS has a smaller carbon footprint and results in less pollution than the manufacturing of alternative materials. And EPS helps create a more sustainable world by making buildings more energy efficient, reducing greenhouse gas emissions, preventing product damage and waste, and reducing shipping fuel usage, just to name a few. We’re constantly working to find new ways to be good stewards of our customers’ visions and of our environment.

SUBSCRIBE

Get Our Latest Insights

Contact Us

Interested in Learning More?

Whether you need a custom solution for a unique project or have a question, we’re here to help.