Shipping and logistics present numerous challenges, including product damage, environmental impact, and cost efficiency. Ensuring that goods arrive safely while minimizing waste and expenses is a top priority for businesses.

Protective packaging solutions, such as molded foam packaging, temperature-controlled containers, and sustainable materials, play a crucial role in addressing these concerns. This article explores key considerations, industry-specific solutions, and best practices for effective protective packaging.

Key Considerations in Protective Packaging

Product Fragility

The required level of protection varies based on the product’s vulnerability to impact, compression, and environmental factors. Fragile items, such as electronics and medical devices, need specialized protective foam packaging to prevent breakage.

Shipping Environment

Transportation exposes products to various risks, including shock, vibration, moisture, and temperature fluctuations. Packaging must be engineered to withstand these hazards while preserving product integrity.

Cost Efficiency

Balancing cost and effectiveness is essential. Over-packaging can drive up expenses, while inadequate protection can result in damaged goods, returns, and lost revenue. Optimizing packaging design helps achieve the right balance.

Sustainability of Packaging Materials

Eco-friendly packaging solutions are increasingly in demand. Recyclable and biodegradable options, such as biodegradable EPS, offer an environmentally responsible alternative to traditional protective packaging.

Types of Packaging Solutions

Temperature-Controlled Packaging

For temperature-sensitive shipments, EPS foam containers deliver exceptional thermal insulation. Solutions such as XDS™ Extended Duration Shipping containers and molded coolers maintain stable internal temperatures for pharmaceuticals, perishable foods, and biotech materials. These solutions comply with ISTA and ASTM testing standards to ensure product safety.

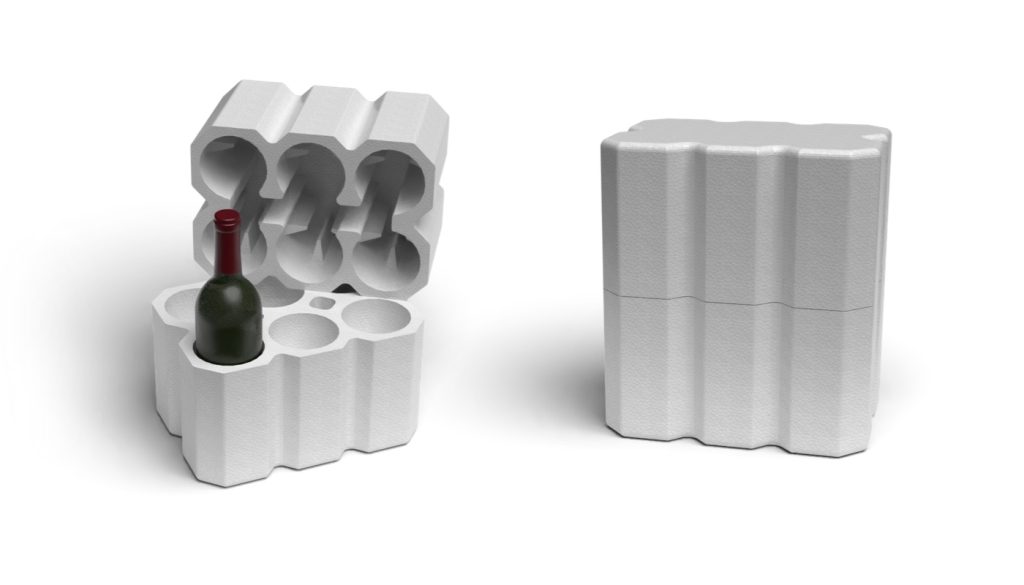

Expanded Polystyrene (EPS) Foam Packaging

EPS foam packaging is widely used due to its lightweight structure and excellent impact resistance. It can be custom-molded to fit specific products, offering superior protection. Common applications include electronics, medical devices, industrial components, and food and beverage packaging.

Biodegradable and Recyclable EPS Foam

Biodegradable EPS provides the protective benefits of traditional EPS while incorporating biodegradable additives that accelerate decomposition. This sustainable packaging option meets growing industry demands for environmentally friendly solutions. In many cases biodegradable foams can be substituted for traditional EPS.

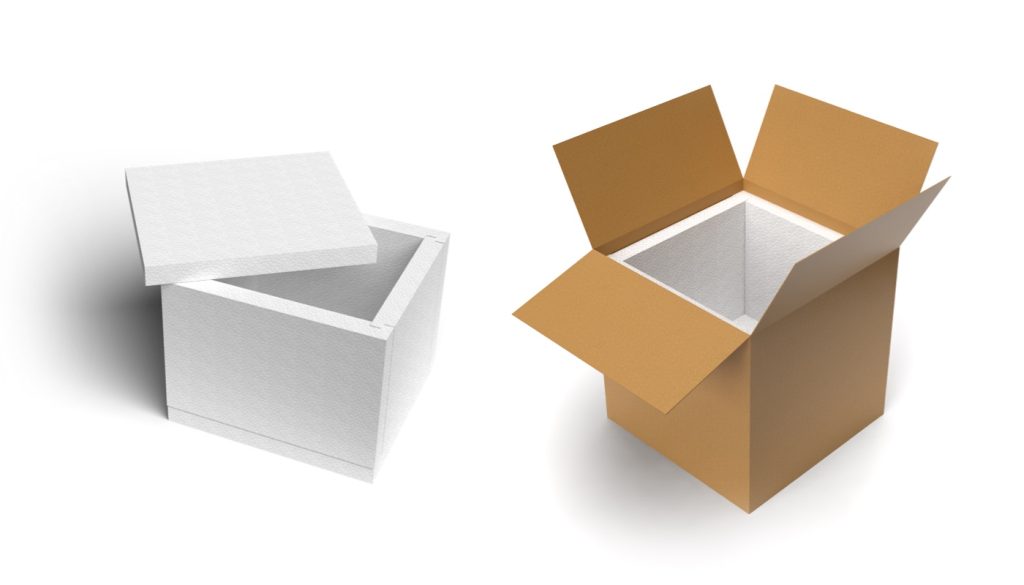

Corrugated Packaging with Foam Inserts

Combining EPS foam inserts with corrugated boxes creates a hybrid packaging solution. The inserts absorb shock and provide cushioning, while the outer box ensures durability. 6-panel box liners offer additional stability for high-value shipments.

Custom Shape-Molded Protective Packaging

Using advanced CAD-CAM technology, custom shape-molded protective packaging is tailored to meet the needs of industries such as aerospace, automotive, biotechnology, and appliances. This precision-engineered approach reduces movement and prevents damage during transit.

Industry-Specific Packaging Solutions

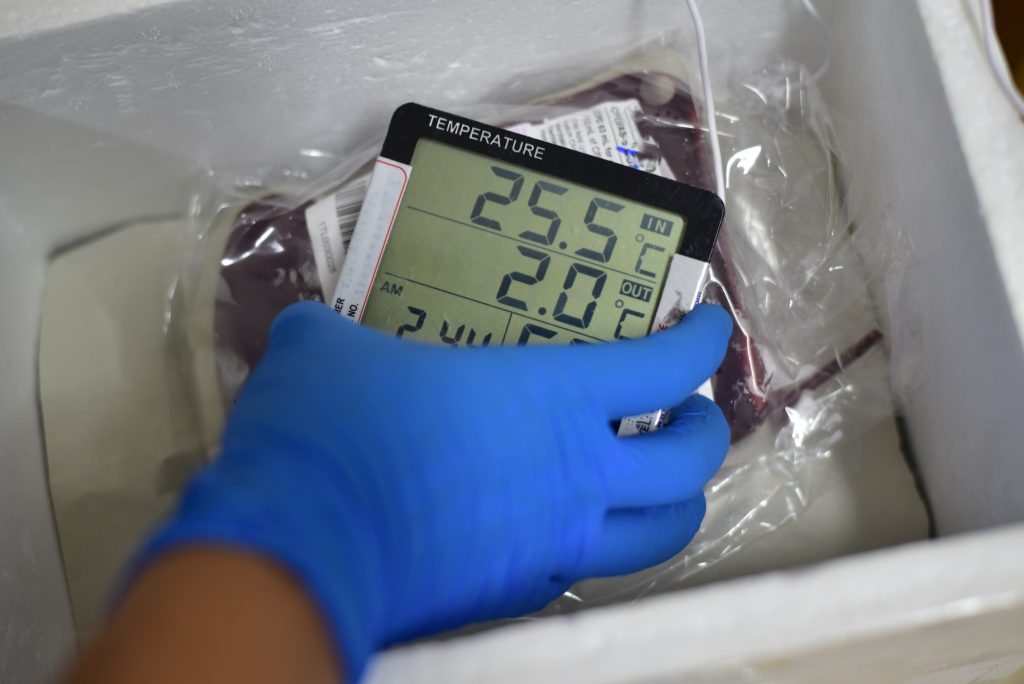

Cold Chain Logistics

Alleguard Cold Chain Solutions offer insulated EPS containers that maintain temperature stability for perishable shipments. These packaging solutions are essential for pharmaceuticals and biologics, ensuring product efficacy during transportation.

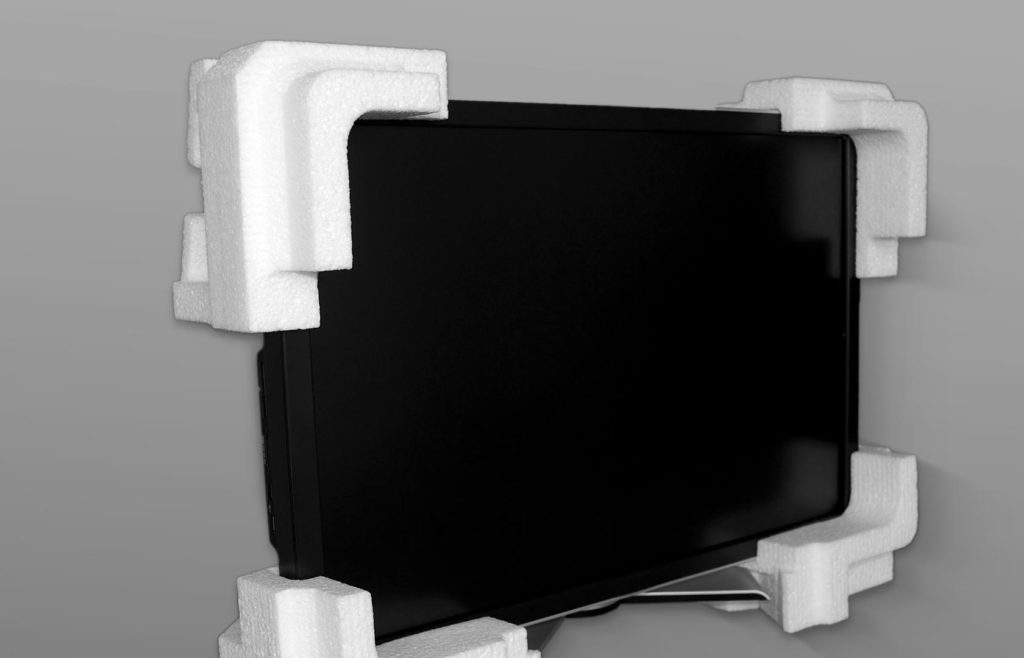

Electronics & High-Value Products

Sensitive electronics require anti-static EPS packaging to protect against static discharge and physical damage. Custom-molded EPS foam safeguards laptops, circuit boards, and high-value electronic devices during shipping.

Industrial and Automotive Components

Industrial and automotive parts are susceptible to damage during transit. High-density EPS foam packaging absorbs shock and prevents movement, while custom shape-molded inserts provide additional stability.

Best Practices for Effective Packaging

Testing and Quality Assurance

Ensuring compliance with ISTA, ASTM, and UL standards is critical for protective packaging solutions. Rigorous testing verifies that materials provide adequate protection under real-world shipping conditions.

Right-Sizing Packaging

Optimizing packaging size minimizes material waste, reduces shipping costs, and enhances sustainability. Right-sizing ensures a secure fit while maintaining necessary protective features.

Sustainable Strategies

Recycling programs and reusable packaging solutions contribute to environmental responsibility. Implementing EPS recycling initiatives reduces landfill waste and supports sustainability efforts.

Custom Solutions

Each industry has unique packaging requirements. Custom-engineered protective packaging solutions provide optimal protection while addressing specific shipping challenges.

Why Alleguard

Alleguard leads the industry in protective packaging, offering innovative and sustainable solutions for a wide range of applications. By utilizing advanced molded foam packaging and temperature-controlled containers, businesses can enhance product protection, reduce costs, and improve sustainability.

Partner with Alleguard for custom-engineered protective packaging solutions tailored to your industry’s needs. Learn more at alleguard.com