Creating proper window and door openings in Insulated Concrete Forms (ICF) construction makes a big difference in a building’s performance. Traditional methods can be messy and wasteful, often leading to errors in measurements and sealing issues. That’s where AmBuck™ comes in: an easy-to-use, precision-made ICF window buck specifically designed for ICF projects.

What Is AmBuck™?

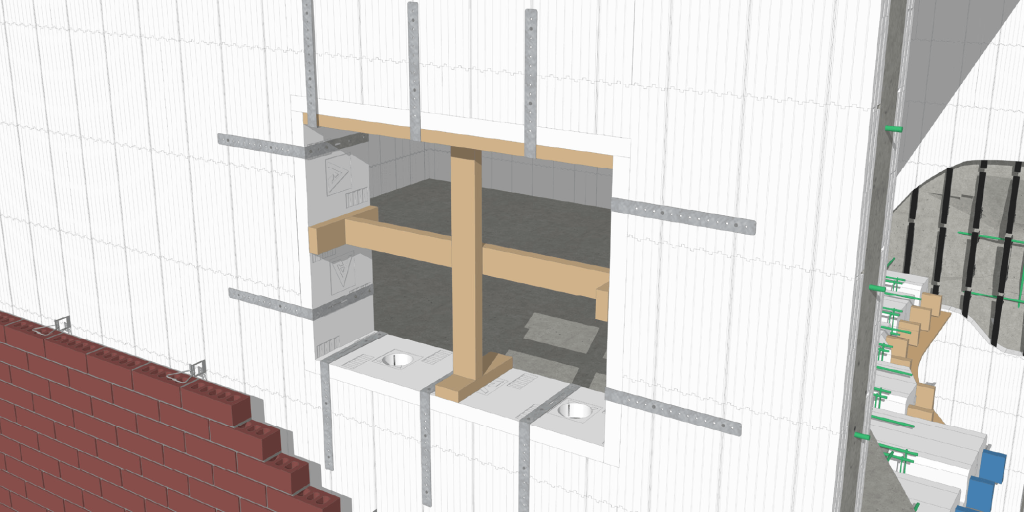

AmBuck™ is an Expanded Polystyrene (EPS) based, ICF window buck system designed for making window and door block-outs in ICF buildings easier. Made from high-density EPS, AmBuck™ fits smoothly into your construction plans.

Its main uses include door openings, window openings, and end walls.

AmBuck™ Benefits

Easier Installation

AmBuck™ simplifies the installation process. Its pre-shaped panels fit perfectly into openings, reducing the need for extensive cutting. Contractors can quickly position and secure these panels, saving both time and effort.

Better Energy Efficiency

Because it’s made from EPS, AmBuck™ provides excellent insulation, helping to prevent unwanted heat loss or gain. This leads to lower energy bills and improved comfort inside the building.

Improved Air and Water Sealing

Thanks to its precise fit, AmBuck™ creates a tighter seal around window and door openings, reducing air leaks and moisture intrusion. This helps prevent issues like mold and makes indoor spaces healthier and more comfortable.

Technical Performance

AmBuck™ is designed with specific technical features tailored for ICF use:

| AmBuck™ Technical Performance | |

|---|---|

| Material Specification | Type II (ASTM C578) / Type 2 (CAN/ULC-S701.1) Expanded Polystyrene (EPS) |

| Thermal Resistance | 4.2 F.ft2.hr/Btu per inch (0.74m2K/W per inch) (ASTM C518) |

| Compressive Strength | 20 psi (138 kPA) (ASTM D1621) |

| Compatibility | Compatible with 6” (152mm) and 8” (203mm) core Amvic™ R22 and R30 ICF systems |

Download AmBuck™ Product Data Sheet

Installation Overview

Installing the AmBuck™ system is straightforward and matches seamlessly with Amvic™ ICF. The EPS panels come pre-shaped, minimizing the need for cuts. If trimming is needed, clean straight cuts are easy to make. After placing the panels into the openings, they are squared, aligned, and braced. Once the concrete cures, remove the braces, and your openings are ready for windows or doors.

Download AmBuck™ Installation Manual

Sustainability Advantages

AmBuck™ uses recyclable EPS material, which is great for environmentally friendly building practices. Its precise design also helps cut down on construction waste. Additionally, its insulation properties can contribute to earning LEED points in energy efficiency and sustainable materials categories.

Ideal Applications

AmBuck™ is perfect for various ICF projects, such as:

- Residential, commercial, and institutional buildings

- Projects focused on sustainability and energy efficiency

- New constructions or additions using Amvic™ Insulated Concrete Forms

AmBuck™ is the go-to choice for creating window and door openings in ICF buildings due to its ease of use, strong performance, and sustainability benefits. By choosing AmBuck™, architects and contractors can deliver better building efficiency, simpler construction, and environmentally conscious designs.