Insulated Concrete Forms (ICFs) are a smart choice for below-grade foundation walls. They’re energy-efficient, structurally strong, and relatively simple to install. But even the best ICF system needs proper moisture protection to perform as expected. Without it, water can seep in, damaging insulation, weakening structural elements, and potentially creating issues with air quality.

This guide covers the essentials of ICF waterproofing. You’ll learn about the different membrane types, drainage solutions, and practical techniques to help keep moisture out and your structure protected.

Damp Proofing vs. Waterproofing

What is Damp Proofing?

Damp proofing is a basic defense against moisture. It’s typically used in areas with low water tables or dry soil, where hydrostatic pressure isn’t a concern. While it can block water vapor and minor moisture, it doesn’t hold up when water starts pressing against the wall.

What is Waterproofing?

Waterproofing goes a step further than damp proofing. It forms a complete barrier that resists both moisture and hydrostatic pressure. It’s the preferred method in areas where water buildup or poor drainage is likely.

Key Differences

- Damp proofing handles moisture but not water pressure.

- ICF waterproofing protects against both moisture and hydrostatic pressure.

- While both may meet code, waterproofing offers better peace of mind for long-term protection.

Moisture Protection Requirements

Any wall that retains soil and encloses a livable space needs moisture protection. Local building codes might allow damp proofing in certain conditions, but waterproofing is the more reliable option. For ICF foundations, it’s the best way to prevent leaks, improve energy efficiency, and guard against mold and deterioration.

ICF-Compatible Waterproofing Options

There are several types of waterproofing membranes made specifically for use with ICF construction. Each offers different benefits in terms of installation, durability, and long-term performance.

Self-Adhering (Peel-and-Stick) Membranes

These flexible ICF waterproofing membranes are applied right onto the ICF wall. A primer is often used first to help them stick properly. It’s important to make sure the product is compatible with EPS foam. When applied correctly, they form a reliable, easy-to-detail moisture barrier.

Liquid-Applied Membranes

These go on with a roller, brush, trowel, or spray. Once dry, they create a smooth, flexible coating that conforms to the wall’s shape. Just like with other options, it’s critical to use one that’s safe for use with EPS.

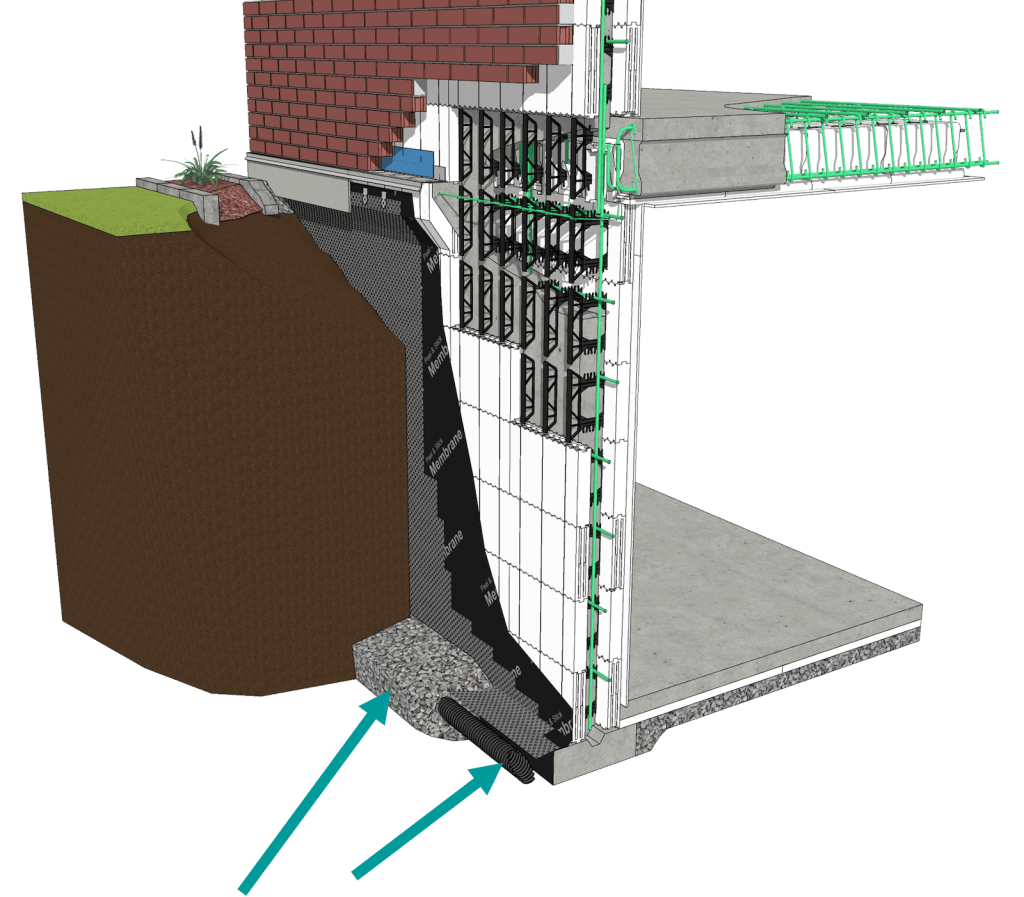

Dimpled Drainage Membranes

Installed over the main waterproofing layer, these ICF waterproofing membranes have inward-facing dimples that create an air space. That space helps guide water away from the wall and reduces pressure. They also offer extra protection during backfill.

Recommended Products

Look for membranes specifically made for ICFs. They should bond well to EPS and stay flexible under soil loads. Products like Soprema Colphene ICF are purpose-built for this kind of work.

Learn More: Recommended ICF Waterproofing Systems

Foundation Drainage Systems

Even a great membrane can fail if water has nowhere to go. Drainage systems take that pressure off your walls and move water away before it becomes a problem. Any wall that holds back soil and creates livable space needs a drainage system. This system should wrap around the entire foundation and sit at or below the footing level, especially when working with a slab-on-grade design.

Key components of a drainage system:

- A perforated pipe or drain tile, placed at or below the footing

- Gravel or crushed stone around the pipe to help water flow

- Drainage and waterproofing work best when used together

Transition at Grade

There are several popular methods for handling the transition at grade level on ICF walls or exposed EPS insulation:

Parging on EPS

A common approach uses a cement-based skim coat to cover exposed EPS insulation. This method often includes reinforcing mesh between layers to create a protective, weather-resistant surface.

Parging Over a Waterproof Transition Membrane

This method adds a membrane first, followed by parging over a mesh surface. It combines water resistance with a clean finish. A membrane with exposed reinforcing mesh like Soprema Sopragrip F is recommended.

Skirting with Cement Board or Metal Panels

In high-traffic or high-impact areas, consider using cement board or metal panels. These can be fastened directly over the EPS to provide long-lasting, low-maintenance protection.

Best Practices for a Dry Basement

The following recommendations help ensure that ICF basements stay dry and warm:

- Make the extra investment and insist on full waterproofing for your foundation or basement walls. For best performance, terminate the waterproofing membrane 2-3” (51-76mm) above grade.

- Build up the ground around your house so that water flows away from the basement walls. Also examine sidewalks, patios, decks, and driveways. These can settle over time and cause water to drain back towards the foundation walls.

- Extend downspouts so that water flows away from the house and does not pool next to the basement walls or windows. If the downspouts are connected to the home’s sewer system, disconnect them.

- Clean debris from gutters regularly. If they overflow even when clean, replace them with larger size gutters and downspouts.

Proper waterproofing is a must for any below-grade ICF project. Damp proofing might meet the minimum standard, but it doesn’t deliver the same protection over time. To build something that lasts, use membranes designed for EPS, install a solid drainage system, and protect exposed foam at grade.

For a system that checks all those boxes, Amvic™ ICF is a proven performer. When paired with smart ICF waterproofing practices, it delivers strength, energy efficiency, and long-term peace of mind.