The complexity of large construction projects can lead to delays, budget strain, and performance issues—especially as skilled labor becomes harder to secure and performance requirements continue to rise. Builders and architects are increasingly adopting innovative, integrated systems to meet these evolving demands. Insulated Concrete Form (ICF) systems offer a high-performance, all-in-one solution that simplifies the building envelope while delivering structural strength, thermal efficiency, and moisture control in a single product.

One System, Multiple Functions

Traditional wall assemblies often rely on numerous layers—framing, batt or board insulation, vapor barriers, air barriers, and additional cladding attachment systems. These multi-component walls require coordination across several trades and introduce greater risk for performance gaps.

ICF systems consolidate these components into one comprehensive system. The expanded polystyrene (EPS) panels offer continuous insulation on both sides of a reinforced concrete core. This core provides robust structural support, while embedded fastening strips simplify the attachment of both interior and exterior finishes.

This integration reduces the margin for error during installation, especially when compared to assembling multiple layers from different products and manufacturers. Builders and designers benefit from a system that ensures consistency, quality, and code compliance from the ground up.

Fewer Steps, Faster Builds

By replacing a multi-step process with a single integrated solution, ICF systems significantly accelerate construction timelines. The blocks are designed for rapid, straightforward stacking, functioning as interlocking modular components that typically require no specialized tools for assembly. Once the forms are assembled and reinforced, concrete is poured into the hollow core, forming a monolithic structural wall while embedding continuous insulation on both sides.

Unlike traditional framing, which often involves separate crews for framing, insulating, and sheathing, ICF installation streamlines the build process. This is particularly beneficial in markets experiencing labor shortages or compressed schedules.

Reduced Jobsite Waste

Material waste is one of the most overlooked inefficiencies in traditional construction. Cutting insulation, vapor barriers, and furring strips to fit around framing can generate significant waste—and cost. ICF minimizes this by eliminating the need for additional layers.

The Amvic™ ICF system minimizes waste by arriving pre-cut, stackable, and ready to install. The system’s built-in structure also means fewer materials are brought to the site in the first place, reducing transportation emissions and on-site clutter. Learn more about the Amvic™ ICF system here.

Any unused or off-cut EPS from ICF blocks can be collected and recycled, contributing to a more circular construction process.

ICF R-value: Better Performance, Built In

A building envelope must do more than meet code—it must maintain performance over time. Traditional wall systems can fail due to inconsistent installation, thermal bridging, or gaps in air and moisture control.

ICF is engineered to overcome these challenges. Its continuous EPS insulation eliminates thermal bridging and ensures stable R-Values. The solid concrete core acts as a natural air and moisture barrier, resisting mold, mildew, and rot. This integrated design reduces the risk of future remediation, improves energy efficiency, and promotes long-term building durability.

Amvic™ ICF blocks are available in R-Values of R22 or R30.

Design Flexibility with Block Variety

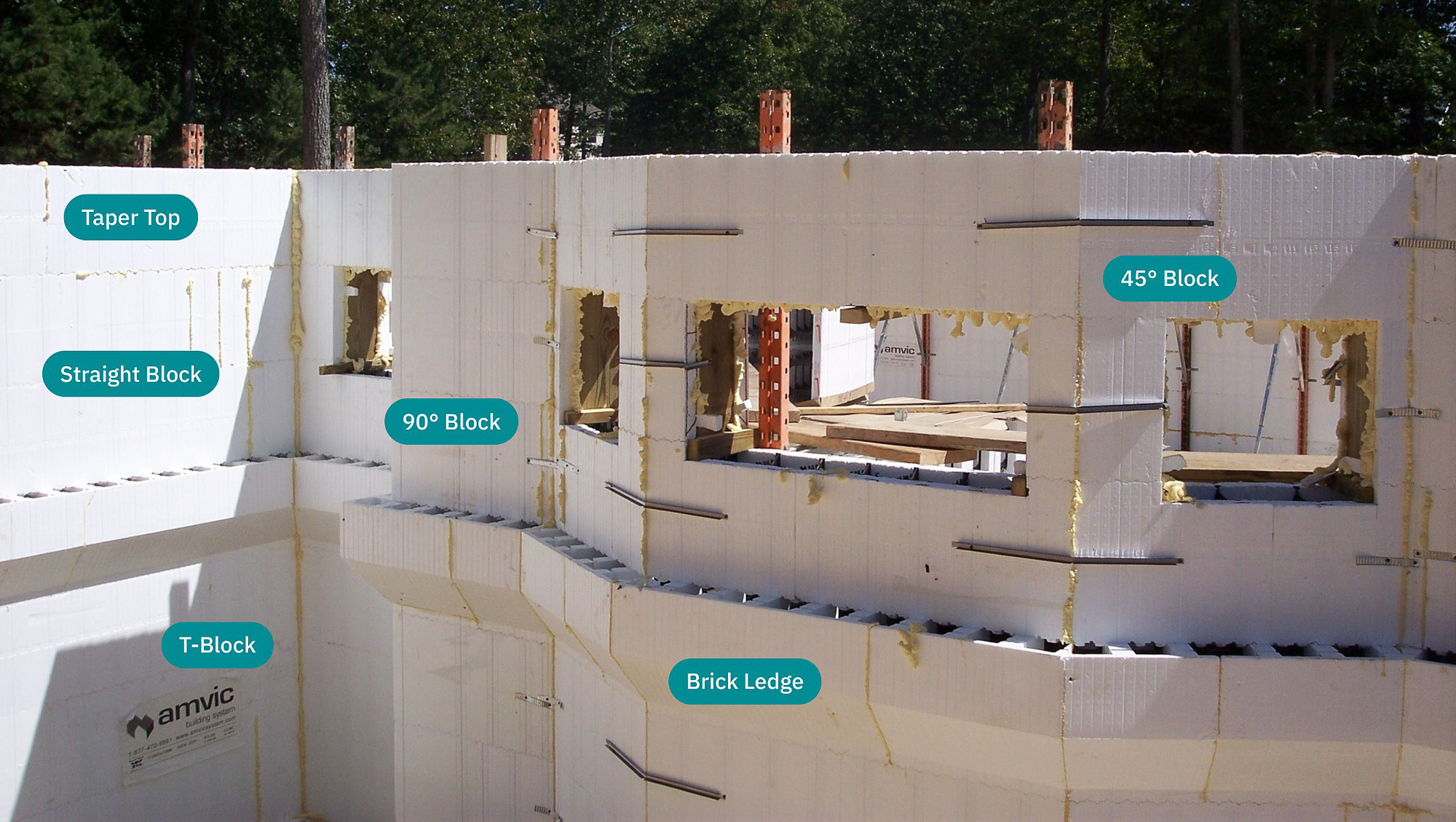

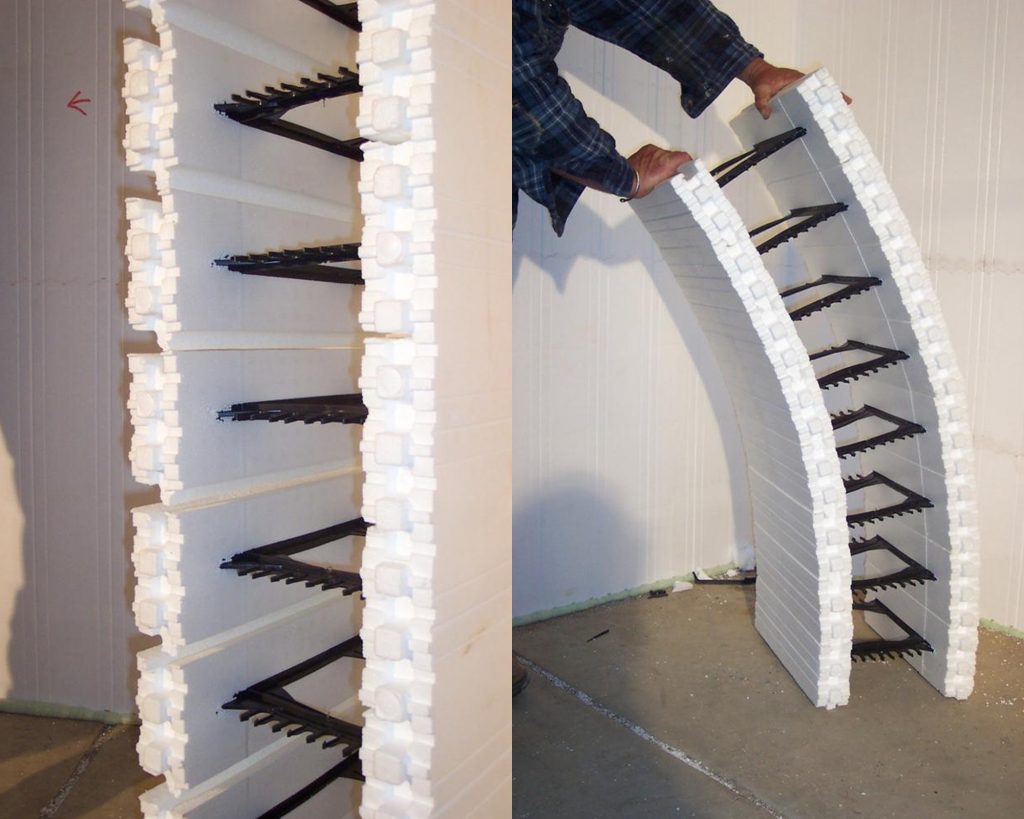

ICF systems function as modular formwork, enabling fast, efficient construction of reinforced concrete walls. Their stackable, interlocking design simplifies installation, while the hollow cores accommodate vertical and horizontal rebar to meet structural requirements. Once poured, the concrete cures in place, forming a continuous insulated wall with exceptional strength and durability.

Each unit is engineered for specific structural and design needs, making it easy to create complex geometries, curved walls, and custom transitions. This design flexibility empowers architects and builders to achieve ambitious layouts while preserving thermal continuity and envelope integrity.

The Amvic™ ICF system includes a comprehensive range of block types, including straight blocks, radius blocks, 90-degree corners, T-blocks, and taper tops.

Compatible with Advanced Detailing

ICFs are more than a structural wall system—they’re an integral part of a modular building envelope solution. By serving as stay-in-place formwork, ICF enables faster and more efficient construction while providing long-term thermal and moisture performance. This modularity allows ICF systems to interface seamlessly with other advanced building technologies.

The Amvic™ ICF system, in particular, is designed to complement Alleguard’s broader suite of building solutions:

- AmBuck™ integrates directly into ICF openings to create airtight, insulated window and door block-outs and end-walls.

- The Amdeck Insulated Floor and Roof System extends the continuous insulation and structural benefits of ICF beyond walls—enabling the creation of a fully encased, high-performance concrete envelope for flooring and roofing.

- Ampex panels offer radiant floor heating integration with ICF foundations.

This ecosystem of compatible products allows designers and builders to create fully integrated, high-performance building envelopes with confidence.

ICFs have revolutionized the way buildings are constructed by offering a unified system that integrates structure, insulation, and air/moisture control. These modular, stay-in-place forms simplify the construction process by reducing steps, minimizing errors, and delivering high-performance results. ICF systems help address challenges tied to energy efficiency, resilience, and long-term durability.

Among the many ICF solutions available, the Amvic™ ICF system stands out as a comprehensive and highly engineered system. It offers superior R-Values, integrated fastening strips, and a full range of block types to support structural and design flexibility. For builders seeking faster installs, architects aiming for thermal continuity, and developers focused on long-term ROI, Amvic™ ICF provides a smarter, performance-driven way to build.